Spiders

- Type CHD Pneumatic Spiders

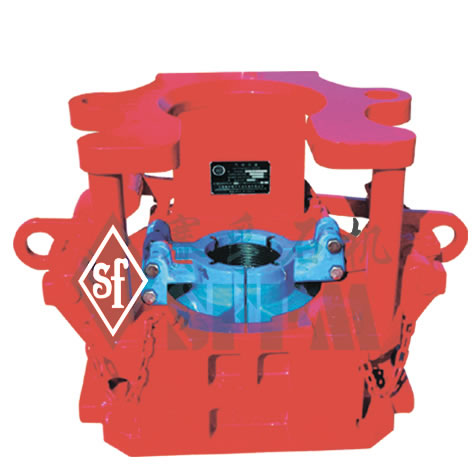

Type CHD pneumatic spiders, also called drill pipe spiders, are applicable for handling drill pipe, tubing, casing or other tubular goods. Pneumatic spiders are widely used in the drilling or work over operation. The drill pipe spiders can accommodate pipe sizes from 1.315 to 5 1/2 inch. And the rated load of pneumatic spiders is 120 ton...

Type CHD pneumatic spiders, also called drill pipe spiders, are applicable for handling drill pipe, tubing, casing or other tubular goods. Pneumatic spiders are widely used in the drilling or work over operation. The drill pipe spiders can accommodate pipe sizes from 1.315 to 5 1/2 inch. And the rated load of pneumatic spiders is 120 ton...

- Type C Pneumatic Spiders

Type C pneumatic spiders are especially suitable for work over operation. Casing pneumatic spiders are designed to handle drill pipe, casing and tubing etc. The pneumatic spiders are suitable for pipe sizes from 1.315 to 5 1/2 inch. And the rated load of type C pneumatic spiders is 80 ton...

Type C pneumatic spiders are especially suitable for work over operation. Casing pneumatic spiders are designed to handle drill pipe, casing and tubing etc. The pneumatic spiders are suitable for pipe sizes from 1.315 to 5 1/2 inch. And the rated load of type C pneumatic spiders is 80 ton...

- Type E Pneumatic Spiders

Type E pneumatic spiders are applicable for handling casing, tubing and drill pipe. This pneumatic tubing spider is designed for medium and heavy-duty operation. Our type E pneumatic spider is one of the most versatile power slips. With the rated load 175 ton, the pneumatic tubing spider can accommodate pipe from 2 3/8 to 7 5/8 inch...

Type E pneumatic spiders are applicable for handling casing, tubing and drill pipe. This pneumatic tubing spider is designed for medium and heavy-duty operation. Our type E pneumatic spider is one of the most versatile power slips. With the rated load 175 ton, the pneumatic tubing spider can accommodate pipe from 2 3/8 to 7 5/8 inch...

- Type QQP Pneumatic Spiders

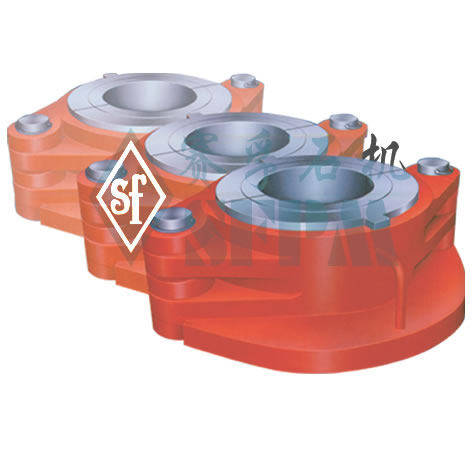

QQP type pneumatic spiders are constructed in a simple and fully enclosed structure, easy to install and operate.

QQP type pneumatic spiders are constructed in a simple and fully enclosed structure, easy to install and operate.

Handling drill spiders use air as the power source and work at a high efficiency with low failure rate...

- Hinged Casing Spiders

Hinged casing spiders, sometimes called tubing spiders, have a capacity of 200 or 500 Tons. The tubing spiders can handle 185/8 and 36 inch casing without insert bowls. And when fitted with insert bowls, the hinged casing spider body can handle 2 3/8-8 5/8in, 9 5/8-10 3/4in, 11 3/4-13 3/8in, 16in diameter casing. All the hinged casing spiders ...

Hinged casing spiders, sometimes called tubing spiders, have a capacity of 200 or 500 Tons. The tubing spiders can handle 185/8 and 36 inch casing without insert bowls. And when fitted with insert bowls, the hinged casing spider body can handle 2 3/8-8 5/8in, 9 5/8-10 3/4in, 11 3/4-13 3/8in, 16in diameter casing. All the hinged casing spiders ...

- Casing Elevators Spiders

Casing elevators or spiders are pneumatically operated power tools for casing operation. These units are capable of handling casing sizes from 4 1/2 to 14in O.D. Casing elevators spiders are designed with capacities of 350 and 500 tons. In terms of 350 tons, casing spiders possess a string load of 3150KN...

Casing elevators or spiders are pneumatically operated power tools for casing operation. These units are capable of handling casing sizes from 4 1/2 to 14in O.D. Casing elevators spiders are designed with capacities of 350 and 500 tons. In terms of 350 tons, casing spiders possess a string load of 3150KN...

As machine tool accessories, spiders are applied to clamp and position work piece by radial movement of the evenly distributed movable claw. They're also called drill pipe spiders or tubing spider. Drill pipe spiders are manufactured with spider body, movable claw and claw drive. The diameter of spider body ranges from 65mm to 1500mm. The tubing spider has a through hole in the middle to accommodate workpiece or bar. In the back of the spider body, there is a cylinder or short taper shape structure connecting with spindle nose directly or with flange plate. Spiders are usually fixed on the lathe, cylindrical grinder and internal grinder. When in use with various dividing devices, drill pipe spiders can also be used in the milling or drilling machine.

- To keep the constant high precision, spiders need right and good lubrication. Incorrect or improper lubrication will lead to some problems. For example, the tubing spider cannot work in the right way when under low voltage; the clamping force and accuracy of drill pipe spiders may be reduced; also spiders have irregular wear or easily get stuck.

- Spiders need applying molybdenum disulphide grease (back color) at least once a day. Apply the grease in the spider mouth until it comes out to the clamping claw or the spider inner bore (the connection between the inner bore protective casing and link nut). However, in the cases that the drill pipe spiders rotate at a high speed or there is a lot of water cutting oil when in use, they'll need more lubrication.

- When operation is over, it's very important to clean the spider body and slide side by a blower gun or similar tools.

- The spiders need disassembling for washing at least once every 6 months. To keep the claw slide side clean and lubricated, we can have a longer use of tubing spider. But if to cut cast iron, cleaning should be done at least once every two months. Do check all the parts regularly to see if any damage happened. Then before assembling, enough grease is needed for dill pipe spiders.

- For different workpieces, we need to apply different clamping ways or to choose a special clamp otherwise the spider service life will be reduced. And when the spider gap is too big, it's better to use a new one.

- Using the antirust cutting oil to keep the spider clumping force.

After long time wear, spiders cannot well center the workpiece. At this time, we can adopt the grinding method to repair the claw inside of three claw spider. This method is simple, economical and effective.

First, we need to prepare a grinding wheel with the diameter smaller than that of spider inner bore. Grinding material is white fused alumina with the particle size of 46#~60#. Then to fix the grinding wheel to the morse taper stick for easy installation onto the lathe tailstock. After moving the claw to touch the grinding wheel, we start the machine tool. When the rotation speed is higher than 960r/min, we need to drive the hand wheel of tailstock to let the grinding wheel move back and forth. Through several grinding, we tighten the claw properly. Then until all the grinding of the claw is well finished, repairing work comes to an end.

As a professional China based manufacturer of drilling tools, including drill pipe spiders, Lanteky® Machine has become a first-level supply member of Chinese Petroleum & Natural Gas Consortium. At the same time, it's also the member of China Petrochemical Material Resources Market. And the company has achieved its own right for products import and export.

Lanteky® Machine

Address: NO.5558 CHUANSHA ROAD, PUDONG DISTRICT, SHANGHAI, CHINA

Postcode: 201306

Email: landy.industry20@gmail.com